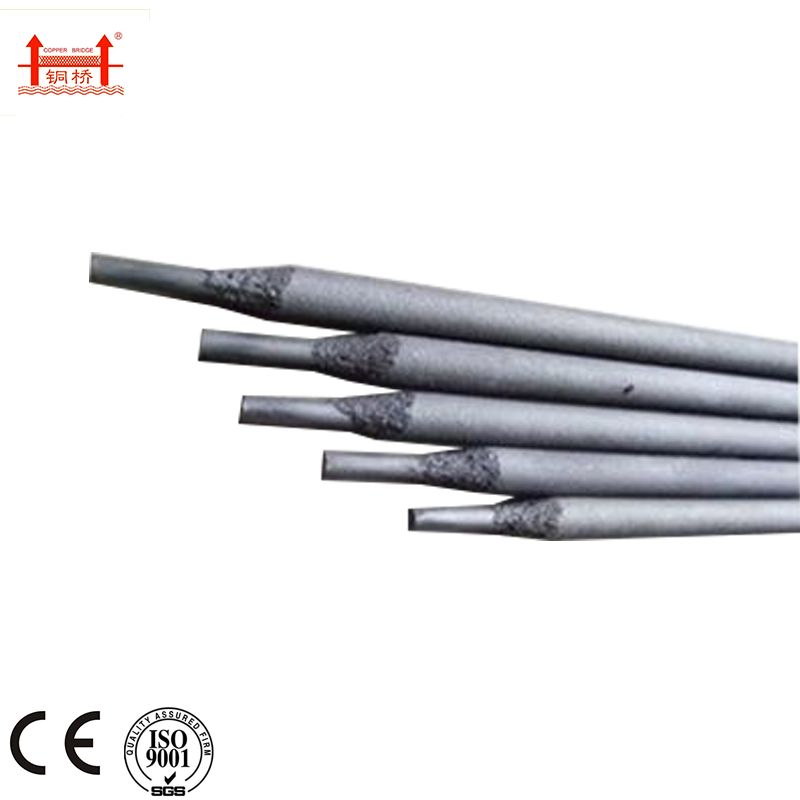

pasokan elektroda las stainless steel aws e309 e309l

Karakteristik lan Aplikasi

TheweldmetaloofE309/309Lngandhut luwih Cr Ni tinimbangE 308/308L.Isine ferrite jumlah cocok ing microstructure, menehi resistance banget kanggo retak panas.Iki dirancang kanggo welding meta sing beda-beda saka gabungan baja ringan nganti stainless steel, baja paduan hardening lan baja kanthi weldability sing kurang.Logam dasar Prop kalebu plat baja tahan karat, strip baja, tabung baja, tabung transfer panas, bar baja tekanan, casting lan forging.

Cathetan babagan panggunaan

1.Clean munggah contaminations ing logam dhasar, alur lan pass kanggo pass karo rerumput stainless steel

2.Maintaining arclength cendhak aspossible Highly dianjurake.Nalika welding karo cara nenun, sawetara mov kudu kontrol ing 2,5 kaping saka kabel kang.

3. Garing elektroda ing 250 ~ 300 ℃ kanggo 60 menit sadurunge digunakake.Njupuk metu consumables kanggo konsumsi dina haif lan tetep ing lingkungan ing 100 ~ 150 ℃ sak proses welding.

4. Gunakake saiki ngisor kanggo nyegah saka retak lan nyilikake pengenceran logam dasar.

Katrangan

| Jinis Elektroda | Pambuka | Migunakake |

| Model: CB-J421 GB: E4313 AWS: E6013 | Iki minangka elektroda baja karbon kanthi lapisan jinis titania. AC DC. Kabeh posisi welding. Wis kinerja welding banget, kinerja operasi sing apik banget, gampang reignition, busur stabil, katon ayu las. | Kanggo welding struktur baja karbon kurang, utamané cocok kanggo welding ing piring lancip lan welding cometic kang mbutuhake manik weld dadi ayu lan nggilap. |

| Model: CB-J425 GB: E4311 AWS: E6011 | Iki minangka elektroda baja karbon kanthi lapisan jinis kalium selulosa. AC DC. Wis kinerja welding banget, katon ayu sawise welding mudhun vertikal, slags kurang lan efficiency welding dhuwur. | Cocog kanggo welding bokong, welding fillet lan welding puteran ing piring tipis, kayata struktur baja karbon rendah kaya stasiun tenaga listrik, saluran udara, tangki minyak trafo, lambung, panel njaba mobil, lsp. |

| Model: CB-J508 GB: E5018 AWS: E7018 | Iki minangka elektroda baja karbon kanthi lapisan jinis hidrogen sing kurang. AC DC. Wis kinerja welding banget, gampang reignition, busur stabil, katon ayu saka las. | Digunakake kanggo welding baja karbon lan struktur baja alloy kurang, kayata 16Mn, etc. |

Komposisi kimia saka logam sing disimpen (%)

| AWS | Komposisi kimia | C | Mn | Si | S | P |

| E6013 | Nilai Jaminan | ≤0.12 | 0.30-0.60 | ≤0.35 | ≤0,035 | ≤0,040 |

| E6011 | Nilai Jaminan | ≤0.20 | 0.30-0.60 | ≤0.30 | ≤0,035 | ≤0,040 |

| E7018 | Nilai Jaminan | ≤0.12 | ≤1,60 | ≤0,75 | ≤0,035 | ≤0,040 |

Sifat Mekanik Logam Deposit (%)

| AWS | Item Tes | Rm (Mpa) | Rel (Mpa) | A(%) | KV2(J) |

| E6011 | Nilai Jaminan Hasil Umum | ≥420440-450 | ≥330≥340 | ≥2222-30 | ≥27(-30°C)50-90(-30°C) |

| E6013 | Nilai Jaminan Hasil Umum | ≥420460-540 | ≥330≥340 | ≥1718-26 | -(0°C)≥47 |

| E7018 | Nilai Jaminan | ≥490 | ≥400 | ≥22 | ≥27(-30°C) |

Arus referensi (AC, DC)

| AWS | Diameter elektroda (mm) | φ2.5 | φ3.2 | φ4.0 | φ5.0 |

| E6013 | Arus Las (A) | 50-90 | 90-130 | 130-210 | 170-230 |

| E6011 | Arus Las (A) | 30-50 | 80-100 | 110-130 | 150-200 |

| E7018 | Arus Las (A) | 60-100 | 80-140 | 110-210 | 160-230 |

Packing

Pabrik Kita

Pameran

Sertifikasi kita